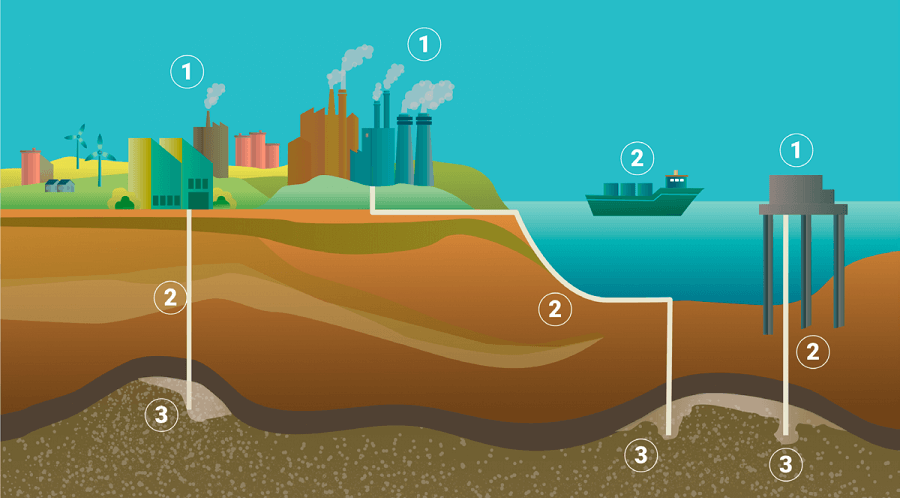

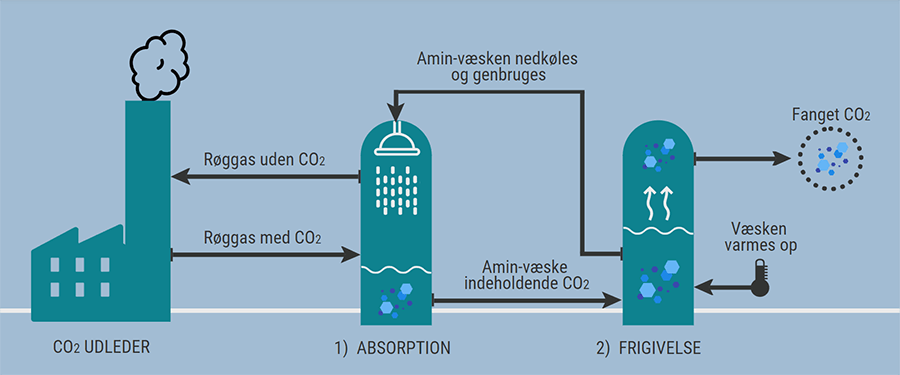

Carbon capture and storage (i.e. “CCS”) is a well-known climate technology that captures CO2 from flue gases and stores it permanently in the subsoil. Politically, it has been decided that CCS will play an important part in meeting Denmark's climate targets. In Denmark, CCS will find its application in selected places in the industrial and energy sectors where it is currently either too expensive or impossible to reduce emissions by other means.

Why use CCS in Denmark?

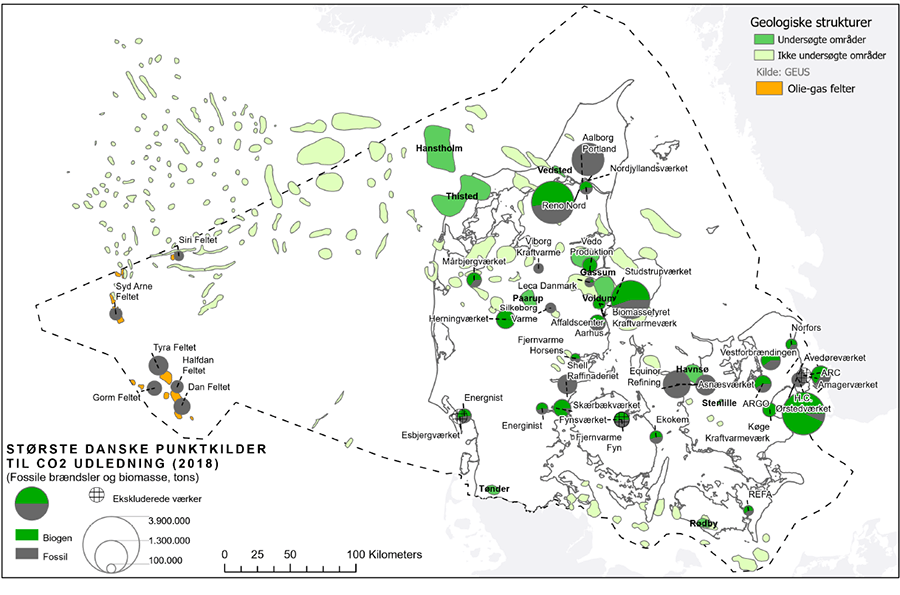

In Denmark, several parallel efforts are underway to limit the amount of CO2 in the atmosphere and ensure compliance with the Danish Climate Act. Efforts focus mainly on energy efficiency and transitioning from fossil fuels to renewable energy. Even if the ambitious Danish targets in these areas are met, some point sources with high CO2 emissions in the industrial and energy sectors will not be able to reduce their emissions to a sufficient degree by means of renewable energy and energy efficiency improvements. It is in these cases that CCS is intended to play a role.

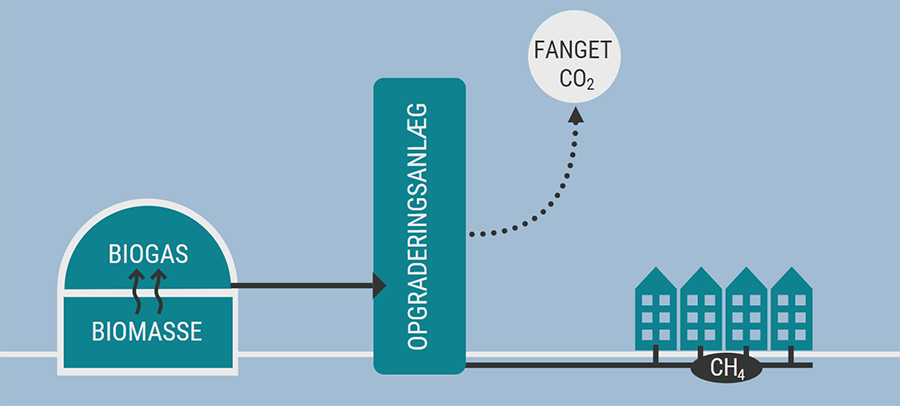

Furthermore, by capturing and storing biogenic CO2 (i.e. CO2 derived from biomass), CCS technology can remove some of the CO2 that has already been released into the atmosphere over the previous decades. This leads to “negative emissions”. Achieving negative emissions will be necessary if we are to reach the Paris Agreement targets of stabilizing global temperatures while achieving the Government's target of 110% CO2 reductions by 2050.

CCS – an important element in meeting Danish climate targets

CCS is important for reducing emissions in the industry and energy sectors and concomitantly for meeting Danish climate targets. It is also important to stress that Denmark’s high ambitions concerning the use of CCS technology do not mean reduced ambitions in relation to the green transition. CCS technology will only be applied to CO2-sources where it makes sense - both for the climate and economically.