CCS is relatively new in Denmark, but the CCS technologies are well-known. There is strong focus on safety and on implementation without adverse impact on the environment.

Capture, transport and storage of CO2 in the subsoil already take place, and the CCS technologies in play are more than 40 years old. Today, CO2 is primarily produced for consumption use in soft drinks and beer. CO2 is also already being transported by lorry and ship in approved ISO tanks.

Storage of CO2 in the subsoil has been practiced for many years in the oil industry for enhanced oil recovery (EOR), a process by which CO2 is pumped down into oil fields to help extract more oil. The practice of using CO2 storage for EOR purposes is not allowed in Denmark, but it is basically the same technology as used in CCS. Knowledge about underground strata available in the oil and gas industry is therefore essential for assessing suitability and potential for CO2 storage. Furthermore, operation of CO2 storage sites applies some of the same principles as are used to operate oil and gas activities today.

According to the Global CCS Institute, there are currently 30 CCS facilities in operation worldwide, 11 facilities are under construction and 153 facilities are being planned.

Examples of European CCS projects

The world's first offshore CCS facility, the Sleipner CCS Project, is located in Norway and has been in operation since 1996. The project is located in the Sleipner field in the North Sea and captures and stores 1 million tonnes CO2 annually. Experience from the Sleipner project helped to inform the EU CCS Directive.

Read more about Norwegian experience with safe CO2 storage

Another Norwegian project supported by the Norwegian state is Projekt-Langskib. The Langskib project initially involves capturing CO2 from a cement factory and a waste incineration plant. The CO2 captured will be transported to Norway's western coast from where it will be stored permanently in the sub-seabed. The transport and storage part of the project, referred to as Northern Lights, has been designed to also accommodate CO2 from other carbon capture projects in and outside Norway and Northern Lights is expected to provide a storage capacity of up to 1.5 million tonnes annually from 2024. A planned second phase of the Northern Lights project will expand the storage capacity to 5 million tonnes annually from 2026/2027.

Among European countries, the Netherlands also has ambitious CCS plans. For example, the Netherlands has launched the Porthos CCS project. According to plans, this project will capture CO2 from industries in Rotterdam and transport it via a shared pipeline system to a depleted natural gas field in the North Sea, 20-25 km off the coast. The partners in the Porthos project expect to be able to store between 2 and 5 million tonnes CO2 annually in 2030.

Examples of CCS projects in Denmark

Project Greensand involves CO2 storage in a sandstone reservoir approx. 1,700-1,800 m below sea level in the depleted Danish Nini West oil field in the North Sea. The consortium behind Project Greensand expects to be able to store up to 1.5 million tonnes CO2 annually in 2025 and up to 8 million tonnes CO2 annually in 2030. The project has been developed in cooperation with GEUS and is being funded by the Energy Technology Development and Demonstration Programme (EUDP). In December 2022, the project was awarded a permit to store up to 15 kilotonnes CO2 for research and development purposes. This pilot project will pave the way for the development of a full-scale project.

Read the press release about the first permit for CO2 storage awarded in Denmark to the Greensand pilot project.

Project Bifrost is another project in the Danish North Sea. This project will store CO2 in the Harald field. The project is a partnership between Dansk Undergrunds Consortium (DUC), Noreco, Nordsøfonden, Ørsted and the DTU Offshore national research centre. The project is being funded by the Energy Technology Development and Demonstration Programme (EUDP). The consortium behind Project Bifrost expects to store 5 million tonnes CO2 annually from 2030 and to mature other parts of the field, which comprise limestone formations.

In 2020, the EUDP awarded approx. DKK 28 million to ARC's (waste incineration plant) Net Zero Carbon Capture project. The final result of this project will inform the decision basis for whether to invest in a full-scale facility able to capture the 480,000 tonnes CO2 emitted annually by ARC.

In addition to projects funded by the EUDP, CCS projects are also being supported under the INNO-CCUS innovation and research initiative. One of INNO-CCUS's projects will establish a pilot facility to capture CO2 at the Aalborg Portland cement factory. Read more about the project on the INNO-CCUS website.

According to the 2020 Climate agreement for energy and industry, etc., CCS will be permitted in Denmark in future, provided the storage is appropriate from a safety and environmental perspective.

Report on CCS: experience gained about safety, nature and the environment

Geological storage of CO2 is covered by Annex 1 of the Danish Environmental Assessment Act and therefore requires a full environmental impact assessment, see section 15 of the Act. However, pilot and demonstration projects with CO2 storage volumes below 100,000 tonnes are exempt from this requirement and this type of project is instead covered by Executive Order no. 974 of 22 June 2022 on geological storage of CO2 volumes below 100 kilotonnes for research, development or testing purposes.

Pipework and capture facilities and other activities are also covered by the Environmental Assessment Act, as well as by other relevant environmental legislation.

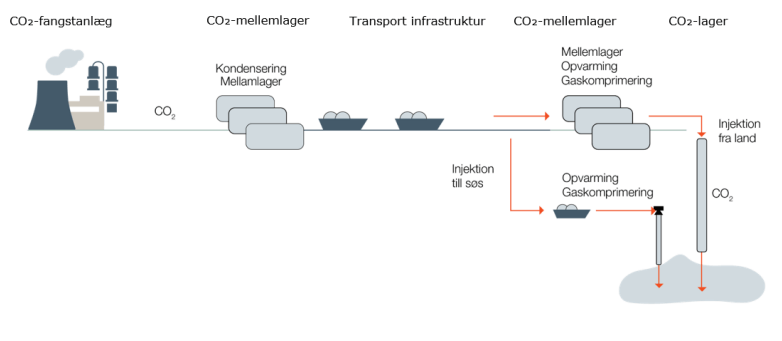

The CCS value chain involves three steps: capture, transport and storage. Different authorisations and new sector couplings are required for each step. Because of this and because of the complex interface to various legislative frameworks, several authorities are involved in safety and environmental work in relation to CCS. The Danish Energy Agency works closely with these other authorities to ensure an efficient process that takes appropriate account of safety and the environment.

Figure illustrating the CCS value chain from capture to storage

Web-accessible alternative to the figure: The CCS value chain from capture to storage

The figure illustrates the various steps in the CCS value chain. The final outline of the value chain will differ depending on the specific project. The example shown includes intermediate CO2 storage. Intermediate storage can be established at Danish ports that can store CO2 from various CO2 point sources temporarily. From here, the CO2 can be transferred to ships for onwards transport to an offshore storage site.

Read the report on CCS: experience gained about safety, nature and the environment (2021)

International obligations

Denmark is obligated to comply with various requirements for safety and environmental protection in relation to CCS under the auspices of the EU and a number of international agreements. For offshore activities, these obligations follow from the London Convention and Protocol, for example, as well as the OSPAR Convention and the Helsinki Convention (HELCOM), all of which aim to protect the marine environment. Several safety and environmental aspects are moreover regulated by the CCS Directive (Directive 2009/31/EC of the European Parliament and of the Council of 23 April 2009 on the geological storage of carbon dioxide). In addition, CCS is covered by current Danish environmental and risk assessment legislation, including the Danish Environmental Assessment Act, the Danish Subsoil Act and the Executive Order on impact assessments in connection with offshore projects.

CO2 makes up approx. 0.04% of the atmosphere. The CO2 stems from human and animal respiration, with the air exhaled by humans and animals containing approx. 3.8% CO2.

CO2 has low acute toxicity for humans, but can be toxic in large concentrations. Furthermore, large volumes of CO2 can displace the oxygen in an area. Operators and the authorities therefore have to pay heed to safety and environmental risks associated with potential leakage, etc. This will allow for establishing mitigating measures and ensuring appropriate emergency preparedness and response.

Leakage or release

CO2 is neither explosive nor combustible, but at high enough levels it can displace the oxygen in the air. If CO2 is released, it will quickly blend with the air outdoors. The blending time depends on wind and weather conditions, and on whether release is at high or low terrain.

On the basis of several studies, the UK Health and Safety Executive has estimated impact distances for CO2 releases. For sudden but limited releases from tankers or large storage tanks, for example, they estimated an impact distance of 120-300 m. This means that if people or animals remain stationary within this radius of the location of the accident, the risk of asphyxiation due to lack of oxygen will be very low, i.e. 1-5%. In situations with continuous releases from a leaking well head, for example, the estimated impact distance was 100-200 m.

Monitoring of international CO2 storage sites has shown that the CO2 remains in the storage reservoir and no accidents or large CO2 releases have been observed from any of the existing geological storage reservoirs. However, there is strong focus on environment, health and safety.

CO2 is already being captured and transported, for example in food production, and requirements for risk and environmental management are therefore already in place for these areas. The requirements and risk preparedness are being expanded and scaled up in response to future large-scale projects.

Risk management and continuous monitoring are important elements in addressing environment and safety concerns. International CO2 storage projects include extensive monitoring programmes during preliminary investigations, and during operation and decommissioning of the storage facilities. Similar requirements have been or will be included in Danish terms and conditions for CCS permits. For example, this includes requirements for monitoring the CO2 in the storage facility through seismic measurements of the subsoil. Seismic measurements can help to identify whether stored CO2 in the subsoil moves and monitor the pressure on the sealing layers. Pressure and temperature in the well, on the seabed/earth's surface can also be monitored. Furthermore, gauges can be installed at well sites to measure CO2 levels in the air.

The risk preparedness of operators is subject to approval by the Danish Working Environment Authority (WEA), and operators can be certified under various international safety standards.

Storage permits require operators to carry out thorough baseline investigations of geological, geographical and environmental conditions before a site can be approved for storage. Solid knowledge about the storage and its geological properties, continuous monitoring and thorough preliminary investigations are a prerequisite for handling the risk of major CO2 releases. Seismic surveys ensure knowledge about the geology and geography in the area. For example, so that sites chosen for storage are located in areas with low tectonic activity and where there is a strong top sealing strata.

Seismic surveys are used to map the Danish subsoil to identify areas with strong CO2 storage potential. GEUS is in the process of mapping these areas through ongoing surveys. Individuals interested can join GEUS and experience these surveying activities on visitors' days.

What are seismic surveys?

Seismic surveys send acoustic waves into the underground. The acoustic waves are reflected differently by the different types of geological strata in the subsoil, and they are also reflected differently where there is a transition from sandstone to claystone, for example. An extremely sensitive microphone can capture the acoustic waves reflected back, and produce a diagram of the waves. Geologists can then interpret the diagrams, and if they have extensive knowledge about the subsoil in the area, for example from drilling activities, they can determine the location and type of layers indicated by the diagram.

The Danish Energy Agency can authorise seismic surveys. There are certain requirements for this, the objective of which is to ensure the surveys are performed without significant impacts on the environment or human health.

Read more about seismic mapping on the GEUS website

Seismic surveys on land are typically performed from roads: two small buggies send out small vibrations and the vibrations reflected back are then captured by geophones located on the roads.

Photo: Specially designed buggies conducting seismic surveys

Web-accessible alternative to the photo: Specially designed buggies conducting seismic surveys

The photo shows how seismic surveys are conducted. Two small, specially designed buggies drive along a paved road sending vibrations into the ground and subsoil using a heavy vibrator weight. The buggies tow a long series of sensitive microphones, called geophones, which capture the acoustic waves that are reflected back. Geophones are also placed on the ground in various places throughout the area being surveyed.